Trenchless Drain Repair Services

Trenchless sewer repair, also known as no-dig drain repair, is now the most common method for fixing pipework due to its relatively quick turnaround with minimal disruption. This reliable technique offers low environmental impact and long-term cost-effectiveness. Unlike traditional pipe replacement, which requires extensive excavation to replace faulty sections, trenchless solutions allow for repairs to be made without the time, inconvenience, and expense of digging.

The trenchless approach utilises the Cured-in-Place-Pipe (CIPP) method. Essentially, this involves feeding a textile-based liner tube impregnated with resin into the damaged pipe section from an upstream insertion point. The resin is then cured or hardened to form a new pipe wall that is fitted, smooth, and resistant to corrosion, giving the repair a long shelf life.

MRMS CIPP Trenchless Repair Solutions

Our team of skilled engineers is fully experienced in delivering trenchless sewer repair services to the highest standards. Our trenchless solutions typically involve the following stages to ensure quick, efficient, and long-lasting repairs with minimal disruption:

CCTV Inspection

A CCTV condition survey of the pipe sections identifies where drain repair is needed and our team then advises on the most effective solution, both in terms of method and costs.

Debris & Root Removal

Debris, blockage or tree roots in the pipe are cleared to prepare the pipe sections for repair. We use both high-speed cutters and Ultra High Pressure (UHP) water jetters to clear and cut the roots.

Wet-Out Stage

This stage involves the process of impregnating a textile liner tube with the resin mixture. The liner is usually made from polyester, fibreglass cloth, carbon fibre or another resin-impregnable material.

Inversion

The liner tube is inverted into the pipe section via an upstream access point such as a manhole. Air pressure is then applied, expanding the tube to fill the pipe. The resin is forced to the outside and sticks to the existing pipe wall.

Curing

The resin is cured, or hardened, via a few different methods including ambient, hot water, steam or light-curing (UV and LED). This hardening of the resin creates a fitted, smooth and corrosion-resistant new pipe wall.

Reconnection

If during the process of relining it was necessary to cover over any branch line openings in the pipe works, robotic or UHP water jetters are utilised to re-establish the pipe connections.

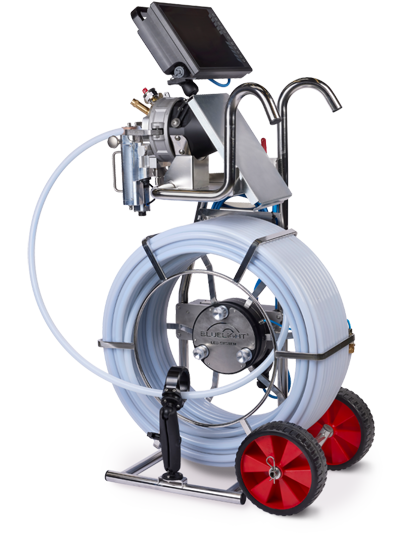

Bluelight CIPP

In keeping with the MRMS culture, our trenchless sewer repair division utilises the latest technology to lower environmental impact, minimise disruption, and save on long-term costs. Bluelight CIPP is a cutting-edge trenchless solution that uses blue light LEDs to cure the pipe lining.

Blue light has a short wavelength, allowing for more time between the wetting out and curing stages by reducing the possibility of premature hardening. The high-intensity light provides a deeper and more complete cure, with significantly faster curing times—a 50-foot sewer line could be fully cured in under 10 minutes using this method.

To find out more about our Bluelight CIPP system and its many advantages over more traditional CIPP methods, read our article on the subject.

6 Advantages of CIPP Trenchless Repair

Much Less Disruptive

Less Expensive

Longer Lasting

Safer

Improved Performance

Eco-Friendly

Working with MRMS

We guarantee the highest quality of service and safety at all times.